Bilge Treatment Systems

Megator Corporation has entered into a cooperative agreement with MYCELX Technologies to represent its oil-free water technologies to the marine industry in Europe and the Americas.

PureShip BilgeKleen®

The World’s Only Stand-Alone Polishing Unit for Emulsified Bilge Water

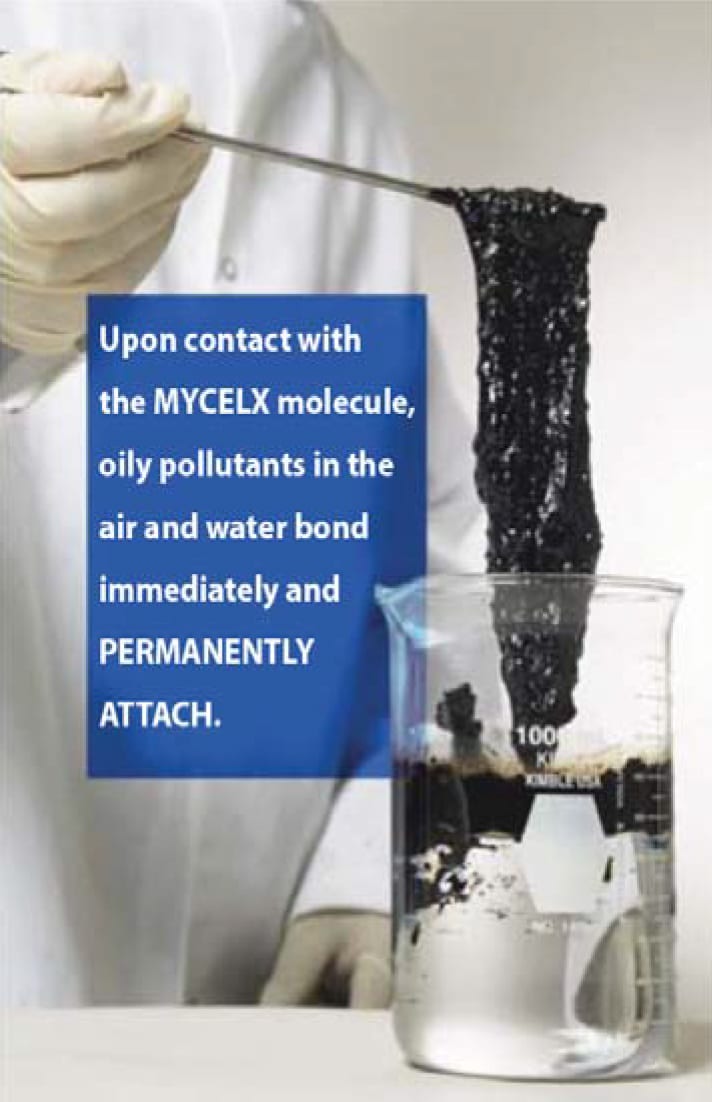

Real life example of the MYCELX oil collection v on the right and un-infused melt-blown PP filter regarding oil saturation and re-entrainment.

We also offer:

- Replacement polishing filter cartridges infused with MYCELX to replace inferior and ineffective filter media cartridges

HRM Filters

- OilClean® filter housings for MYCELX water treatment on work boats and recreational boats

Preconditioning options:

- Capturing slugs of bulk oil and particulate before an OWS or stand-alone polisher

- For use in front of membrane systems to prevent face plugging, fouling and damage to membranes from bulk oil and particulate that would otherwise require expensive replacement.

OilClean® Filters

MYCELX snippets:

are ideal for high capacity gross oil and solids removal from water. Typical flow capacities of MYCELX Snippets media based systems: 20gpm – 10,000 gpm

Key Benefits of MYCELX Snippets:

- High capacity gross oil and solids removal from water

- Permanent immobilization of the oil in the MYCELX media.

- Does not build pressure drop even upon complete saturation with oil and solids i.e. it does not foul or clog

Snippet (SN) Coalescing Media Bags

Oil Removing Bag Filter (POEL):

extended life filter media is delivered in a standard bag filter package, with a large format MYCELX oil removal core insert, to make a standard bag filter a powerful oil removal filter. Typical flow capacities of MYCELX POEL media based systems: 20gpm - 50 gpm (per P2 bag)

Key Benefits of MYCELX POEL:

- Gross and fine oil and solids removal from water

- Permanent immobilization of the oil in the MYCELX media.

- Particle pre-filtration not necessary

MYCELX POEL

Myclex filters chosen for NOAA’s Fisheries Fleet.

Applying polymers to filters to enhance oil affinity has been attempted without success multiple times. The reason: all man-made sequentially assembled polymers swell with oil, quickly resulting in prohibitive dP. MYCELX is novel in that it renders oil into a cohesive viscoelastic mass upon contact. VE materials densify and contract when sheared. Oil captured by MYCELX filters contracts and adheres to the filter without resulting in dP. The viscoelastic immobilization of the oil also results in the smallest possible footprint as re-entrainment is eliminated.

EMULSIFIED OIL

- Only stand-alone polishing unit certified to meet or exceed requirements of IMO MEPC 107(49)c for emulsified bilge water, sizes 1, 2.5, 5, 10 cubic meters per hour units

- Is sensitive enough to treat emulsified oily streams (IMO and NAVAL bilge test emulsions), while robust enough to capture unemulsified oil at the same time without plugging up or failing due to high dP – absence of this capability is the most common mode of failure for shipboard UF bilge water systems

- Will discharge highly emulsified bilge water at under to 15 ppm with no visible sheen

GENERAL

- Can be engaged pre- or post-existing OWS to assure compliance to IMO and local regulations

- Can be used as stand-alone bilge treatment for smaller vessels, especially in environmentally sensitive areas

- Will protect downstream UF and other treatment from fouling

- Can be engaged as needed to assure sheen-free discharge post 60(33) and other type OWS

Lloyd’s Register Certificates available

MYCELX filters are used on the Galapagos Islands fleet, discharging sheen-free water at 5 ppm or better, which protects the islands’ unique ecosystems including that of the marine iguana.

Bilge Treatment System Resources

MYCELX Technical Data

MYCELX Snippets Oil Removal Technology

MYCELX ELOR – Oil Removing Bag Filter

Emulsion Breaker Polishing Filter Cartridges

Hydrocarbon Removal Matrix (HRM) Cartridges

OilClean® Systems

PureShip BilgeKleen® Polisher

Snippet (SN) Coalescing Media Bags

Versimat

Evaluation of IMO and Naval Type Bilge Cocktails

Galapagos Islands

MyCelx Filters Chosen for NOAAs Fisheries Fleet